The ultrasonic flow meter is designed to measure the fluid velocity of liquid withina closed conduit. The transducers are a non-contacting, clamp-on type, which will provide benefits of non- fouling operation and easy installation.

.jpg)

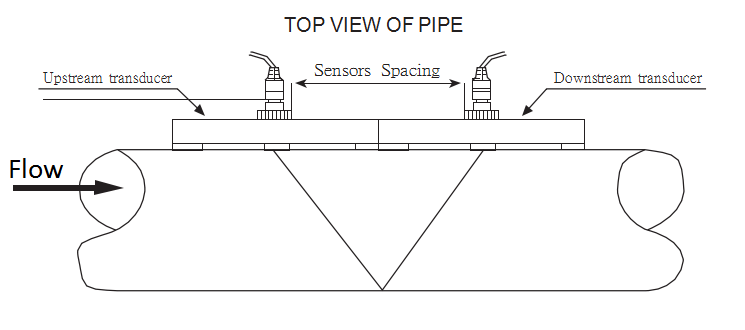

V-method installation is the moswidely used mode for daily measurement with pipe inner diameters ranging from 15 millimeter to 200 millimeter. It is also called reflective mode or method.

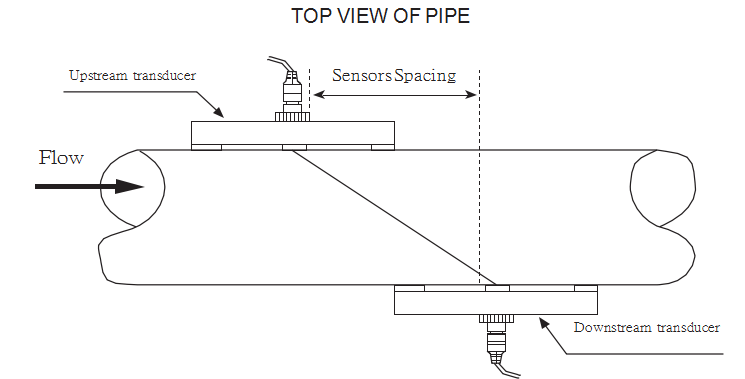

Z-method is commonly used when the pipe diameter is between 300 millimeters and 500 millimeters.

W-method is usually used on plastic pipes with a diameter from 15 millimeters to 100 millimeters

.png)

.jpg)

Product parameters

|

Linearity |

0.5% |

|

Repeatability |

0.2% |

|

Accuracy |

±1% of reading at rates>0.2 mps |

|

Response Time |

0-999 seconds, user-configurable |

|

Velocity |

±32 m/s |

|

Pipe Size |

20mm-6000mm |

|

Rate Units |

Meter, Feet, Cubic Meter, Liter, Cubic Feet, USA Gallon, Imperial Gallon, Oil Barrel, USA Liquid Barrel, Imperial Liquid Barrel, Million USA Gallons. User configurable. |

|

Totalizer |

7-digit totals for net, positive and negative flow respectively |

|

Liquid Types |

Virtually all liquids |

|

Security |

Setup values Modification Lockout. Access code needs unlocking |

|

Display |

4x8 Chinese characters or 4x16 English letters |

|

Communication Interface |

RS-232C, baud-rate: from 75 to 57600. Protocol made by the manufacturer and compatible with that of the FUJI ultrasonic flow meter. User protocols can be made on enquiry. |

|

Transducers |

Model M1 for standard, other 3 models for optional |

|

Transducer cable length |

Standard 2x10 meters, optional 2x 500 meters |

|

Power Supply |

3 AAA Ni-H built-in batteries. When fully recharged it will last over 10 hours of operation. 100V-240VAC for the charger |

|

Data Logger |

Built-in data logger can store over 2000 lines of data |

|

Manual Totalizer |

7-digit press-key-to-go totalizer for calibration |

|

Housing Material |

ABS |