Philemon smart electromagnetic flow meter is hallmarked by its high performance and reliability that are based on successful, field-proven technology.

|

Brief Introduction

Electromagnetic flow meter is one of the most popular flow meters. Flange type electromagnetic flow meter has been used for more than 50 years worldwide. It is widely used for all conductive liquids in every industry, such as water, acid, alkali, milk, slurry etc. |

.jpg) |

Introduction and Application

.jpg) |

|

|

|

| Water Treatment | Food Industry | Pharmaceutical Industry | Petrochemical |

|

|

|

|

| Paper Industry | Chemical Monitoring | Metallurgical Industry | Coal Industry |

| « Measurement is independent of fluid density, humidity, temperature, pressure and conductivity. |

| « There is no obstructive in the conduit and no pressure drop, and the straight pipe required is relatively short. |

| « The sensor is equipped with the advanced processing technology that provides excellent immunity to negative pressure. |

| « The LCD of the converter makes it easy to read during daylight and in darkness. |

| « Parameters can be set up using infrared touch nubs without having to open the cover of the converter. |

| « The converter has alarm function for selfdiagnosis, empty load test, high and low limit of flow, two-stage flow value, etc. |

| « It's applicable not only to general process, but also in tough applications such as mining, papermaking, pastry, etc. |

| « High-pressure sensor adopting PFA lining technology is resistant to high pressure and negative pressure, and is especially good in industries of oil, chemistry, etc. |

.jpg)

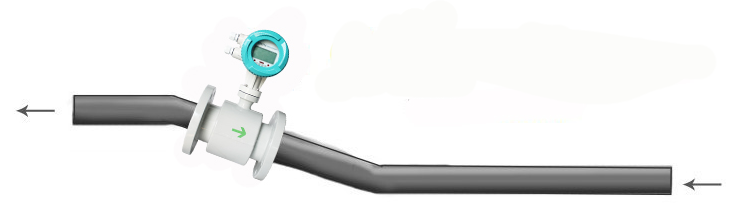

Installation Notice

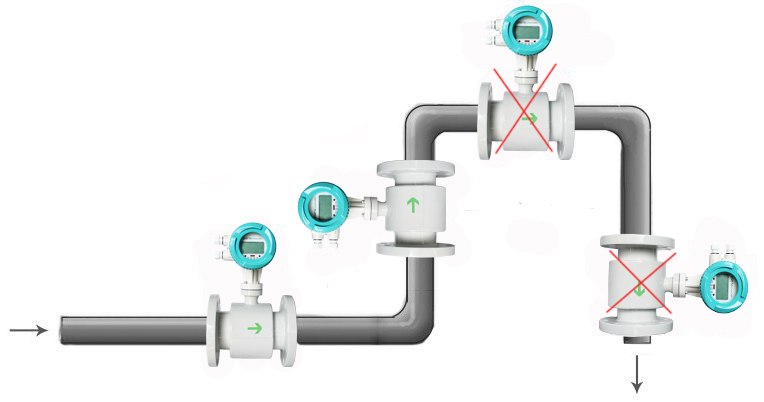

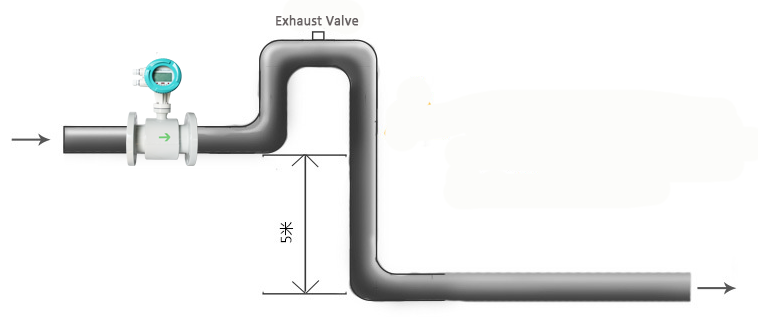

Installed at the lowest point and vertical upward direction Install exhaust valve at the downstreat of flow meter

Don’t install at the highest point and vertical downward diection when drop is more than 5m

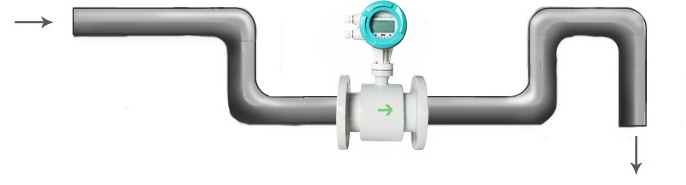

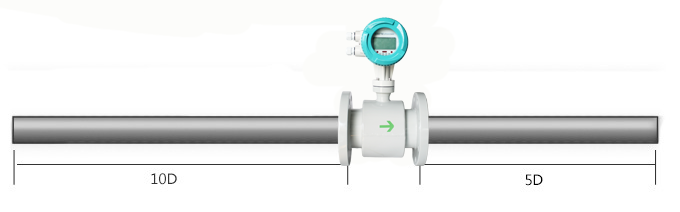

Installed at the lowest point when used in open drain pipe Need 10D of upstreat and 5D of downstreat

exit of pump

.jpg)

|

Size |

DN3-DN3000mm |

|

Nominal Pressure |

0.6-1.6Mpa(2.5Mpa/4.0Mpa/6.4Mpa...Max 42Mpa) |

|

Accuracy |

+/-0.5%(Standard) |

|

Liner |

PTFE, Neoprene, Hard Rubber, EPDM, FEP, Polyurethane, PFA |

|

Electrode |

SUS316L, Hastelloy B, Hastelloy C |

|

Structure Type |

Integral type, remote type, submersible type, ex-proof type |

|

Medium Temperature |

-20~+60 degC(Integral type) |

|

Remote type(Neoprene,Hard Rubber,Polyurethane,EPDM) -10~+80degC |

|

|

Ambient Temperature |

-20~+60deg C |

|

Ambient Humidity |

5-100%RH(relative humidity) |

|

Measuring Range |

Max 15m/s |

|

Conductivity |

>5us/cm |

|

Protection Class |

IP65(Standard); IP68(Optional for remote type) |

|

Process Connection |

Flange (Standard), Wafer, Thread, Tri-clamp etc (Optional) |

|

Output Signal |

4-20mA/Pulse |

|

Communication |

RS485(Standard), HART(Optional),GPRS/GSM (Optional) |

|

Power Supply |

AC220V (can be used for AC85-250V) |

|

Power Consumption |

<20W |

|

Alarm |

Upper Limit Alarm / Lower Limit Alarm |

|

Self-diagnosis |

Empty Pipe Alarm, Exciting Alarm |

|

Explosion Proof |

ATEX |

| Electrode Material | Applications & Properties |

| SUS316L |

Applicable to industrial/municipal water, wastewater and low corrosive mediums. Widely used in petroleum, chemical industries. |

| Hastelloy B |

Strong resistance to hydrochloric acids below the boiling point. Resist against oxidable acids, alkali and non-oxidable salts. For instance, vitriol, phosphate, hydrofluoric acids, and organic acids. |

| Hastelloy C | Exceptional resistance to strong solutions of oxidizing salts and acids. For example, Fe+++, Cu++, Nitric acids, mixed acids |

| Titanium |

Titanium can withstand corrosive mediums such as seawater, chloride salt solutions, hypochlorite salts, oxidable acids(including fuming nitric acids), organic acids, and alkali. Not resistant to high purity reducing acids such as sulphuric acids, hydrochloric acids. |

| Tantalum |

Highly resistant to corrosive mediums. Applicable to all chemical mediums except Hydrofluoric Acids, Oleum and Alkali. |

| Platinum-iridium | Applicable to all chemical mediums except for Ammonium salts and Fortis |

.png)

.png)