Introduction

Insertion vortex flow meter works based on Carmen and Strouhal relevant spiral produce and on the theory of the flow relationship. As shown in picture, In the meter body vertical insert a triangular prism root namely the happening of the body, when eddies of medium flow through the table body, in triangular prism behind the alternate produce in opposite directions regular karman swirl,its spiral separation and the flow of the medium frequency F speed by sensing head is proportional to the V detected the number of spiral,can measure the flow velocity,again according tp the table body mouth.

Application

• Liquid

• Dry gas

• Wet gas

• Wet steam

• Dry steam

• Saturated steam

• Superheated steam

Feature:

• Flange&body: integrally forged pieces, it will avoid break down into pieces. 100% SS304 material,we can provide material report.

• Circuit Board: Digital circuit board,anti most of the supplier use analog circuit board,digital circuit board enjoy the advantages of anti-vibration and anti-interference.

• Flow converter: Distinctive modular design, amateurs can operate, disassemble and assemble easily, it will avoid accident risks.

• Welding: adopt the advanced fish scale technology,which makes the welding seam looks nice and smooth.

• Japan OVAL technology with embedded-type sensor, triangular prism will not fall off, we already apply for patent.

• Our medium temperature sensor can measure highest temperature around 350℃,normal it is -40~250℃

.jpg)

.jpg)

.jpg)

|

NOMINAL |

LIQUID(T=20℃ ΡO=1000KG/M3) |

GAS(T=20℃ 101325 PA AIR) |

||

|---|---|---|---|---|

|

Standard Range |

Obtained Flow Range |

Standard Range |

Obtained Flow Range |

|

| 20 | 1~8 | 0.6~12 | 5~50 | 5~60 |

| 25 | 1.5~12 | 0.8~16 | 8~80 | 8~120 |

| 40 | 2.5~30 | 1.5~40 | 20~200 | 18~300 |

| 50 | 3~50 | 2~60 | 30~300 | 30~500 |

| 65 | 5~80 | 3~90 | 50~500 | 50~900 |

| 80 | 8~120 | 5~150 | 80~1000 | 60~1200 |

| 100 | 12~200 | 6~240 | 100~1000 | 100~2000 |

| 125 | 20~300 | 13~390 | 150~1600 | 150~3000 |

| 150 | 30~400 | 15~600 | 250~2500 | 200~4000 |

| 200 | 40~800 | 30~1200 | 400~4000 | 350~8000 |

| 250 | 80~1200 | 40~1600 | 600~6000 | 500~12000 |

| 300 | 100~1800 | 1000~10000 | 1000~10000 | 600~18000 |

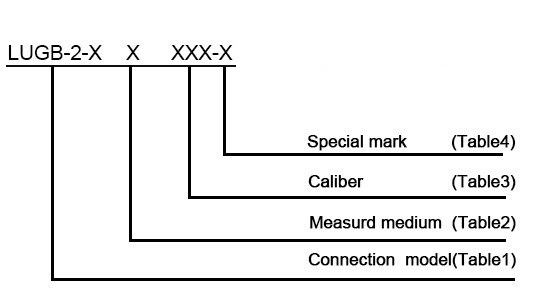

|

CONNECTION MODE |

FLANGE CONNECTION TYPE |

FLANGE CARD INSTALLED TYPE |

INSERTED TYPE | OTHERS |

|---|---|---|---|---|

| Mark No | 1 | 2 | 3 | 4 |

|

MEASURED MEDIUM |

LIQUID |

COMMON GAS |

SATURATED STREAM |

SUPERHEATED STEAM |

OTHERS |

|---|---|---|---|---|---|

| Mark No | 1 | 2 | 3 | 4 | 5 |

| CALIBER | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mark No | 150 | 200 | 250 | 320 | 400 | 500 | 650 | 800 | 101 | 125 | 151 | 201 | 251 | 301 |

| CALIBER | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mark no | 10 | 125 | 151 | 201 | 251 | 301 | 351 | 401 | 501 | 601 | 701 | 801 | 901 | 102 | 122 | 142 | 162 | 182 | 202 |

| FORMAT | COMMON |

STANDARD SIGNAL OUTPUT |

INTRINSICALLY SAFE EXPLOSION-PROOF |

SCENE SHOWS |

HIGH TEMPERATURE |

TEMPERATURE COMPENSATION |

PRESSURE COMPENS ATION |

TEMPERATU RE-PRESSUR E COMPENS ATION |

|---|---|---|---|---|---|---|---|---|

| Mark No | Mo mark | M | B | X | G | W | Y |

Z |